Technics

Customized concepts

Innovative technology in proven quality

Since 1989, GFU – Maschinenbau GmbH has been developing and realizing customized concepts for forming lines to optimize customer-specific production processes in close cooperation with its customers worldwide.

With sound know-how, innovative technology and proven quality, various GFU forming processes can also be combined to produce complex components.

GFU has outstanding concepts ready for both hot forming and cold forming. Customers from the field of regenerative energies and drives, the automotive industry, the aerospace industry, exploration, the construction industry and other industries in reliable technology and solid plants made by GFU.

Machines

Our forming machines

Solutions for many industries

2. High speed end former

Sealing of pipe ends, forming of bottle necks and flanges as a one-piece solution, without welding

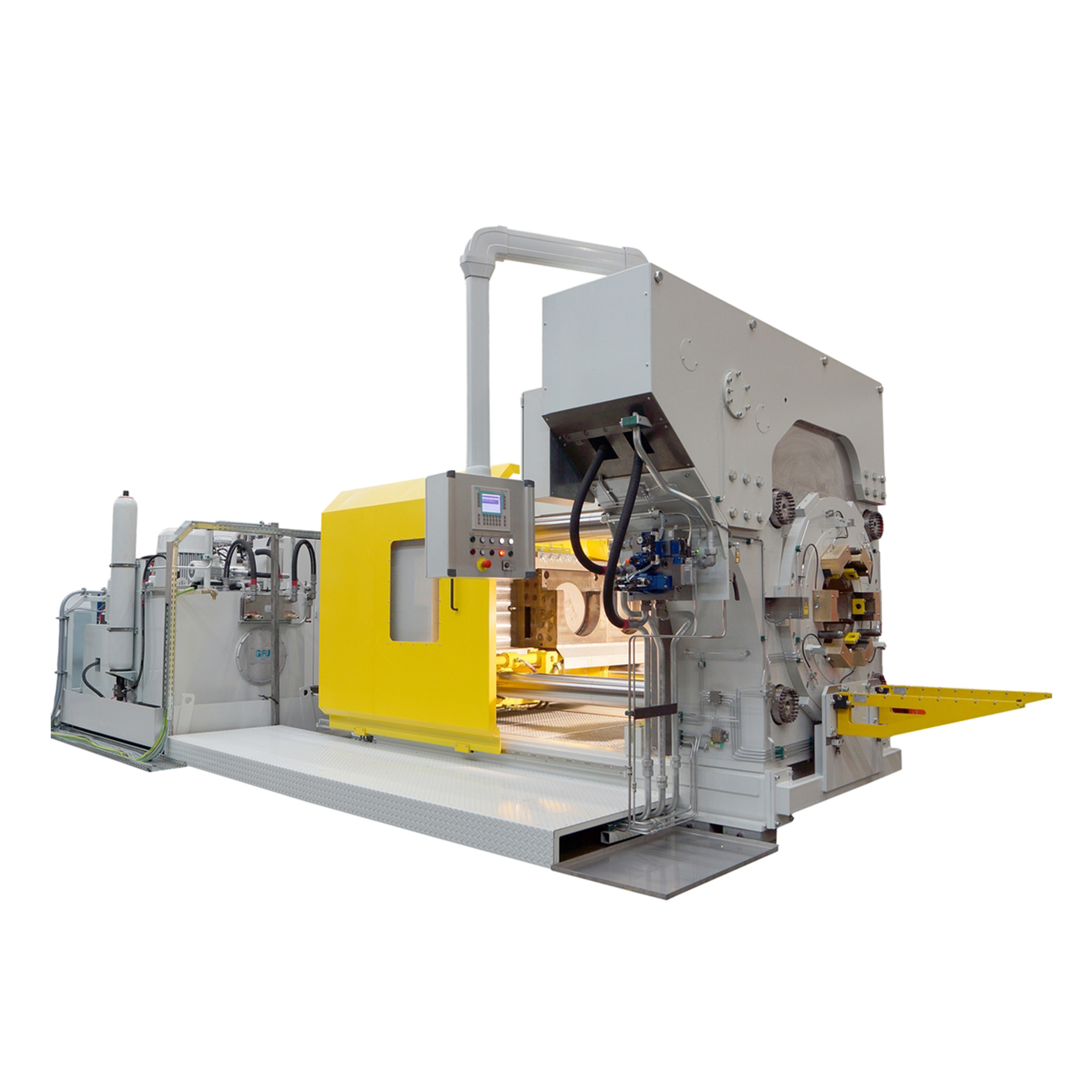

1. Reducing / expanding press / swagers

Mainly cold forming (reducing/flaring) of pipe ends; Ø 10 mm – Ø 508 mm (20″)

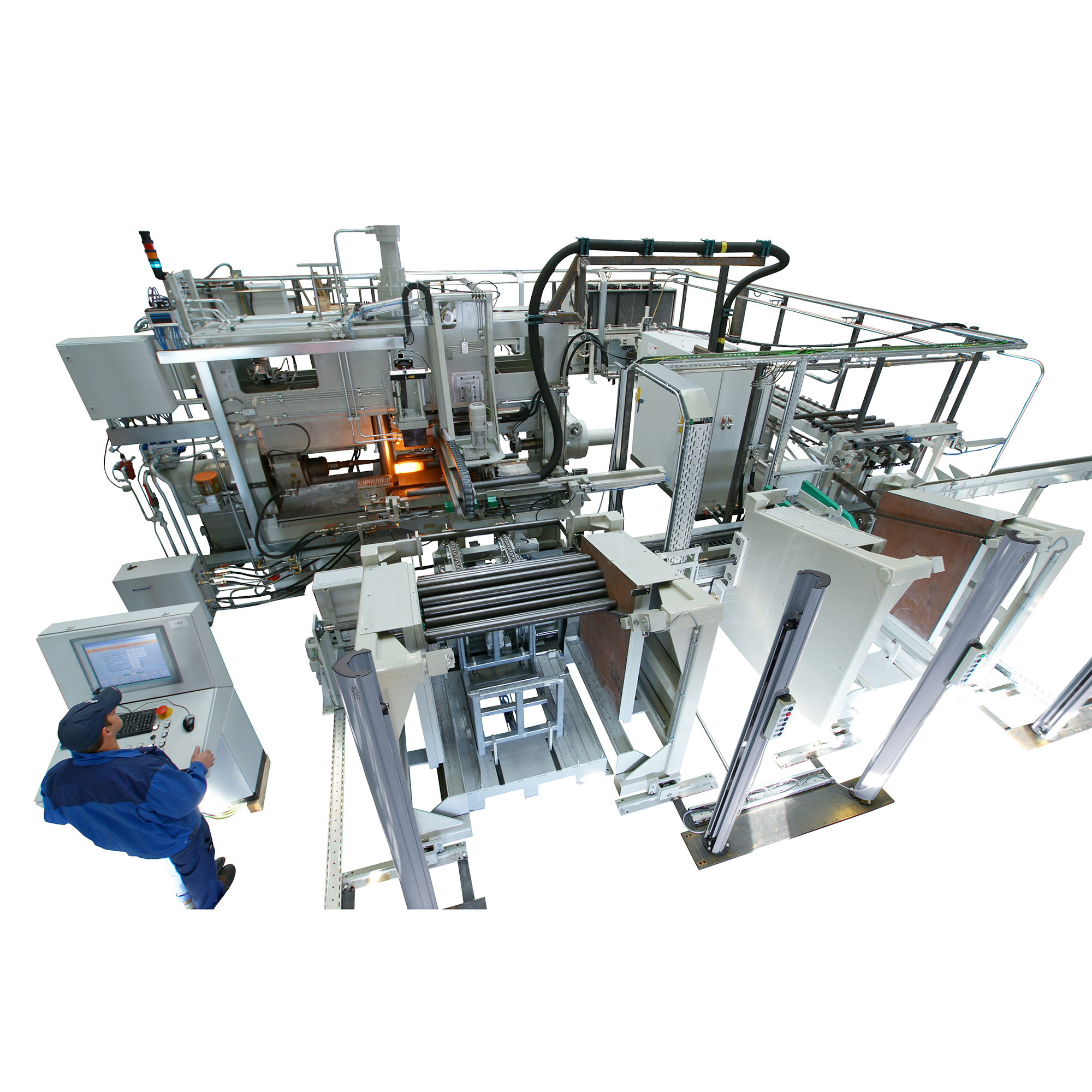

7. Special solutions

Combination of different production technologies to create networked and complete production lines

6. Punching inside/outside

Hydraulic and electric punching unit for tubes with a diameter of Ø 40 – 72 mm (internal punching, external punching)

5. Bending machines / massive forming

Folding and bending of aluminum solid bars as preforms for wishbones / FUCA front upper wishbone or steering knuckle

4. Upsetting machines

Axial upsetting of solid material and pipes Ø20mm- 170mm to increase the cross-sectional area

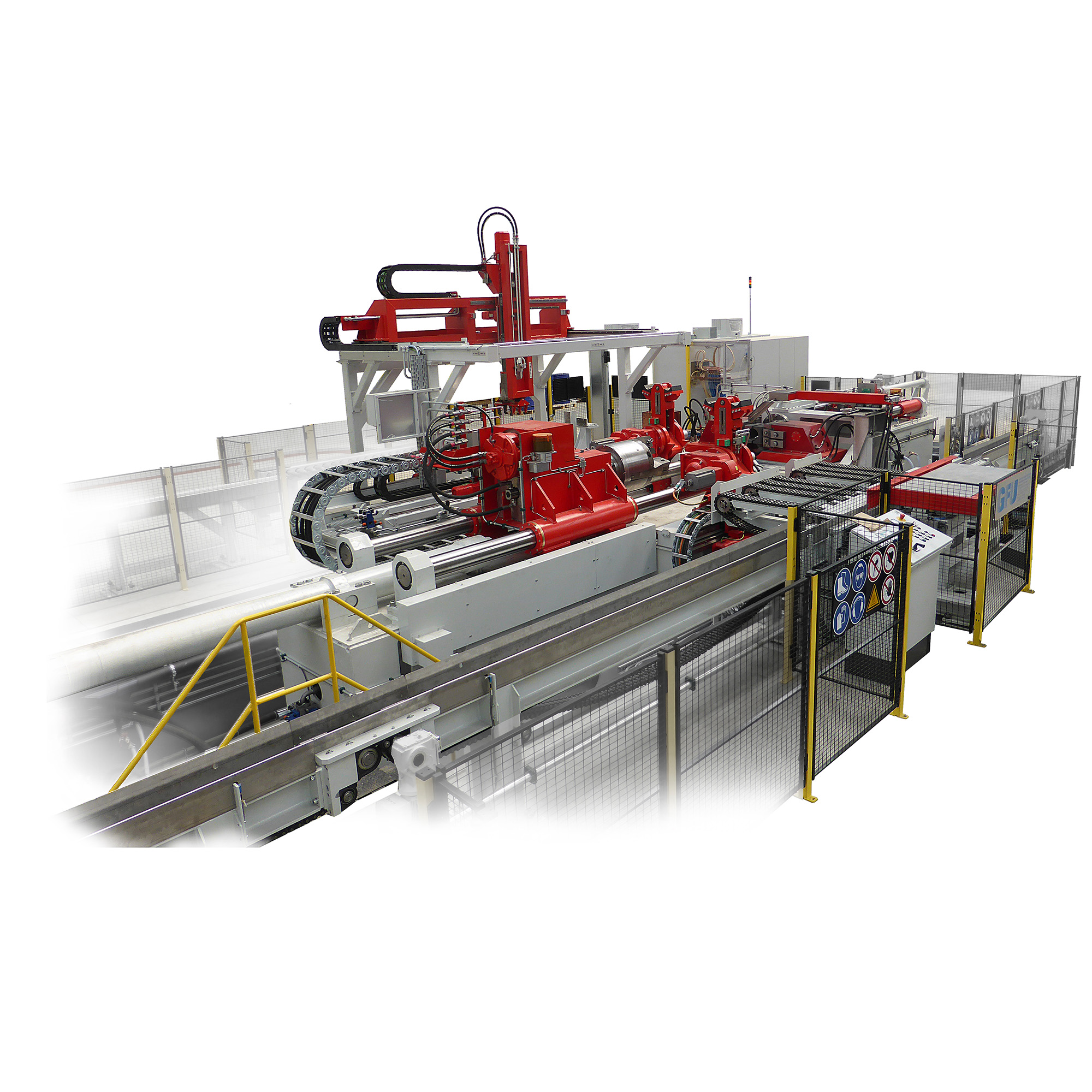

3. Forging machine

Rotationally symmetrical forging of tube ends, e.g. for monoblock axles, stabilizers, drawbars, etc.

2. High speed end former

1. Reducing / expanding press / swagers

7. Special solutions

6. Punching inside/outside

5. Bending machines / massive forming

Idea

From the initial idea to the complete production line

In close coordination with our customers, our experienced team of mechanical and electronic engineers develops individually tailored concepts for each individual task. Long-standing suppliers of machine components, mainly from the local area, also guarantee reliable implementation of the design specifications, as well as consistently high quality of the component.