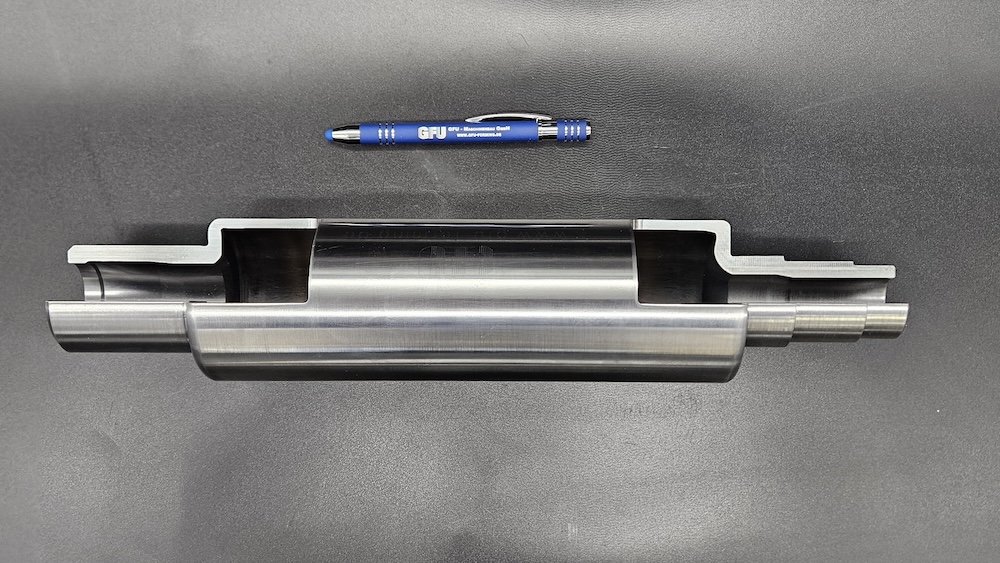

Rotor shafts are core components of electric motors for electric vehicles. They transfer the mechanical energy generated by the electromagnetic interaction between the rotor and stator to the drive shaft, which enables the vehicle to move

Main functions of a rotor shaft:

- Transmission of rotary motion: Rotor shafts are largely responsible for the conversion of electrical energy into mechanical movement of the drive train.

- Stability and precision: The rotor shaft must be able to withstand high speeds and forces, while being manufactured with extreme precision to ensure the smooth operation of the electric motor.

- Weight reduction and energy efficiency: Modern rotor shafts are designed to be lightweight but yet strong, which contributes to the efficiency of the overall vehicle and optimizes the range of electric vehicles.

Challenges in the manufacture of rotor shafts:

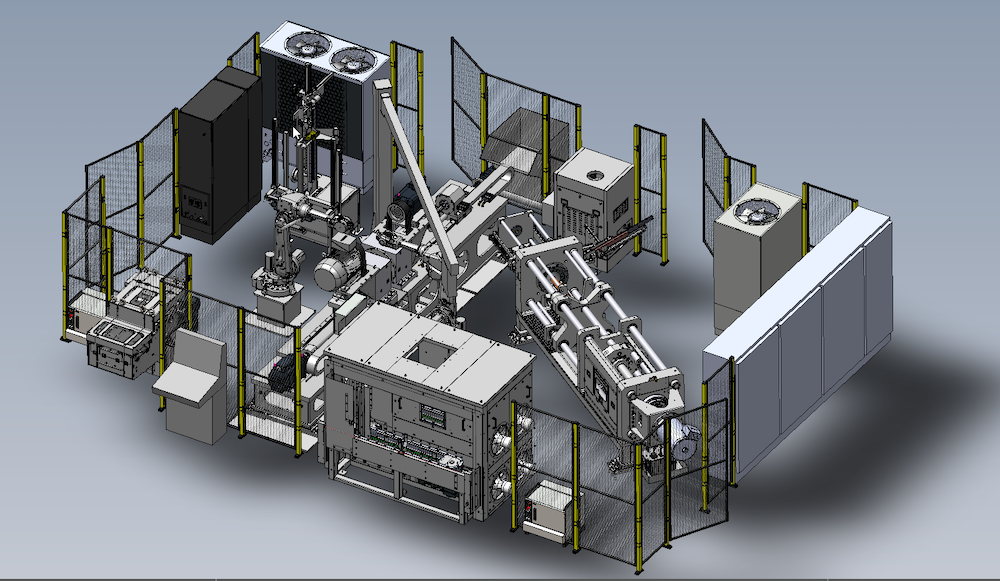

The production of such components requires a combination of the highest precision, material strength (one-piece solutions) and flexibility or combination possibilities in the manufacturing processes (GFU process “high-speed end-forming” + GFU process “Upsetting”) to meet the growing demands of the electric vehicle market.