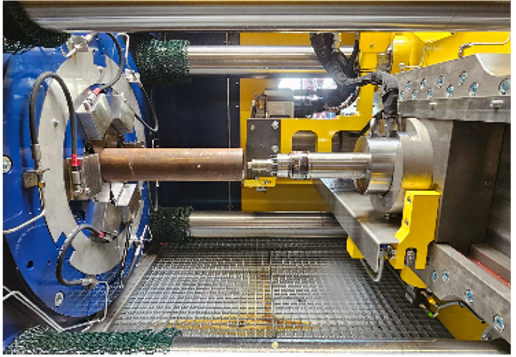

1. chipless forming of premium casings with GFU Maschinenbau GmbH

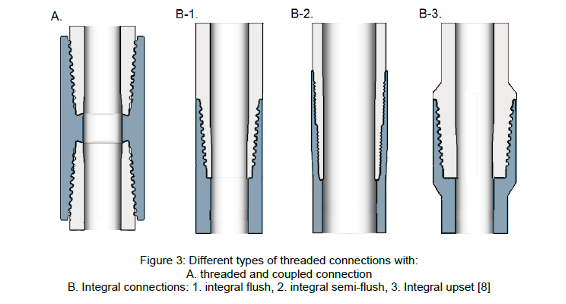

The exploration of crude oil and natural gas is a complex and risky process based on state-of-the-art technologies and materials. In this context, casings / premium casings play a crucial role. These special pipes are not only used to support boreholes, but also to ensure the safety and efficiency of the entire production operations.

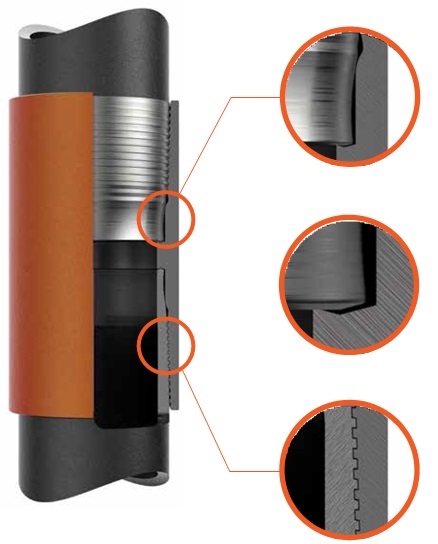

Swaging the pipe ends plays a central role in preparing these pipes for further use. This process is used to optimize the dimensions of the pipe ends of casings to ensure that they meet the high precision requirements for attaching the threads.